Contact Person : Sharon Wang

Phone Number : 0086 156 2308 8800

WhatsApp : +8615623088800

August 17, 2020

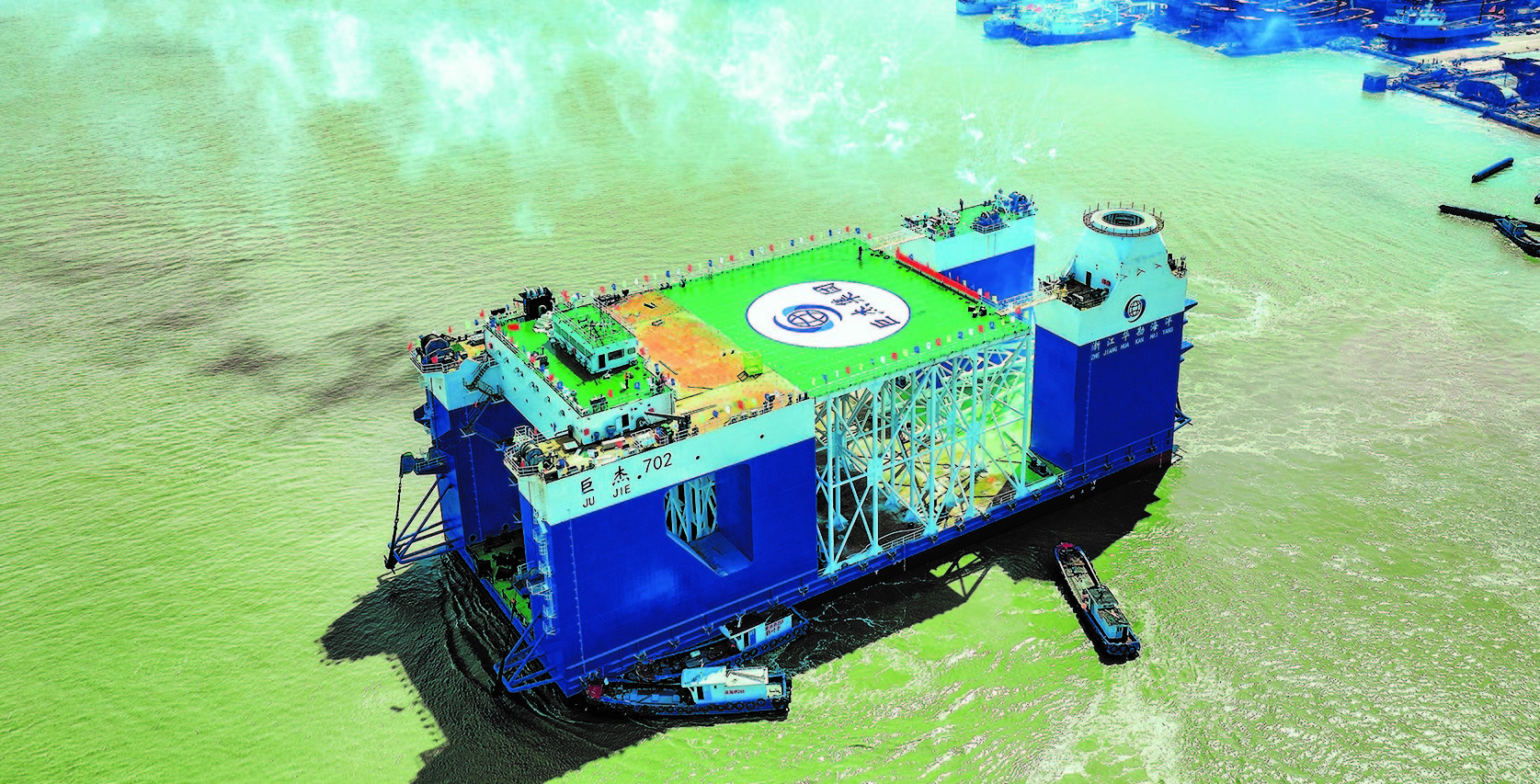

In March 2020, our company provided a large-diameter lifting wire rope for the 700-ton semi-submersible crane vessel "Jujie 702" of Jujie Group. "Jujie 702" was successfully launched at Hepu Zhenhe Wharf in July 2020. The ship is 86 meters long, 141 meters long, 6 meters deep, 24 meters deep, and 10202 tons gross. The ship is used to install offshore wind power equipment with a 700-ton full-slewing crane.

The steel wire rope required by the crane has strict requirements on the yield strength, breaking strength and tensile strength, as well as the rigging of the rope end connection. After negotiation with the engineers of Jujie Group, Shanghai Solar Wire Rope finally reached a long-term cooperation agreement for the supply of the ship's full-slewing crane wire rope.

The steel wire rope used this time is a 6*36WS+IWR structure, a high-strength steel wire rope with a diameter of 100mm, and is coated with a manganese-based phosphating wear-resistant coating. The manganese-based phosphating film completely solves the problem of fretting wear during the use of the wire rope.

![]()

Fatigue test data proves that the fatigue life of manganese-based phosphating-coated steel wire rope far exceeds that of smooth steel wire rope. It is the most advanced technology in the world steel wire rope manufacturing industry.

The service life of steel wire rope is proportional to the fatigue life. The longer the fatigue life, the longer the service life. The average daily use cost of manganese-based phosphate-coated steel wire rope is only about one-third of that of a smooth steel wire rope with the same structure, which effectively extends the service life of the steel wire rope during the use of a semi-submersible crane vessel.

![]()

According to the cooperation requirements, the rope end of the steel wire rope needs to be installed with a single-head or double-head cast American standard closed spelter socket (closed terminal) with a corresponding strength of 1770Mpa to the steel wire.

![]()

The steel wire rope used for hoisting needs to adopt the American standard marine heavy-duty solid thimble with the corresponding strength of 1770Mpa single-end or double-end compression.

![]()

Our advantage is that we can customize different wire ropes and wire rope slings according to the user's use and needs, such as: 6x19, 6x36, 8x19, 8x49 and anti-rotation hoisting wire rope 18x7, 18x19, 35WxK7, etc. The rope has: the end of the steel wire rope is pressed into the heart ring (Thimble Eye), the soft ring(Soft Eye) and the heavy solid thimble , as well as the processing and casting of the open spelter socket, the closed spelter socket , and the pear-shaped mooring socket.

Shanghai Solar Steel Rope Co., Ltd. is a relatively powerful and professional wire rope enterprise in Shanghai. Our company has strong technical force, strict management system, professional sales philosophy, and professional technical personnel. It specializes in wire rope products and lifting solutions. Solutions and wire rope maintenance service companies provide professional products and services for marine engineering, shipbuilding, ports, metallurgy, mining, petroleum, elevator lifting, machinery and other industries.

Enter Your Message